KFS667 Packing bread into transport boxes

The system loads bread products into transport boxes. Products may be whole or sliced bread, or buns, in plastic or paper bags. The system is integrated onto a product conveyor and transport box feeder system. Fully loaded transport boxes are stacked and are ready for transportation.

Capacity: 1800 bags of bread per hour.

VIDEO

KFS194 Packing

Packing products into packages and packing packages into boxes.

In the start of the production line, there is an unloading device, which inputs one package to the line. Packages get packed, after which covers get closed and labeled. Then the packages get moved into the robot cell. In the end, packages get placed into boxes and boxes will be the stacked.

Capacity: package stack unloading rate of 60 packages per minute.

KFS187 Sack palletizing

Sacks are brought from packer to robot's pick place through conveyor. Robot picks a pallet from a stack and puts it in place, after which robot palletizes a sack according to the palletizing pattern. Completed pallet is then moved away from robot's area with a conveyor.

Capacity: palletizing speed of 6 sacks per minute.

KFS185 Box collecting

Automatic collecting of boxes in bakery's dispatch department.

Robot system collects products according to orders and consignments into pallets. Boxes are collected so that they are in the packed into truck by distribution order. The system can collect simultaneously 16 different products.

Capacity: about 4000 boxes a day.

VIDEO

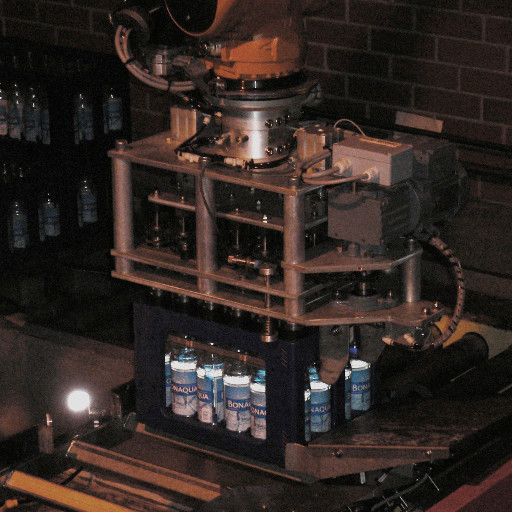

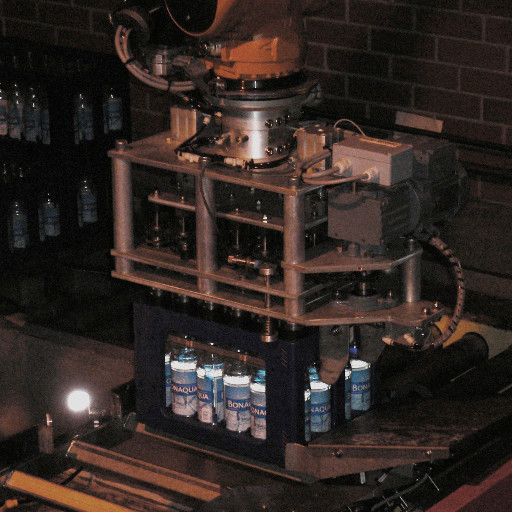

KFS182 Can palletizing

Robot system palletizes shrink wrapped can packages. Packages are turned upside down and then palletized according to the palletizing pattern.

Capacity: palletizing speed of 25 packages per minute.

KFS177 Box packing

Packages are inspected before packaging using a machine vision system. Labels and package edge cleanliness are checked during the inspection. Acceptable packages are packed into boxes and then moved forward.

Capacity: packing speed of 75 packages per minute per robot cell, and more than 200000 packages per day.

VIDEO

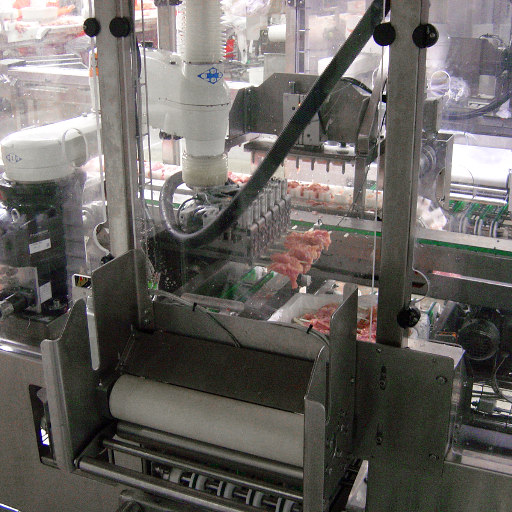

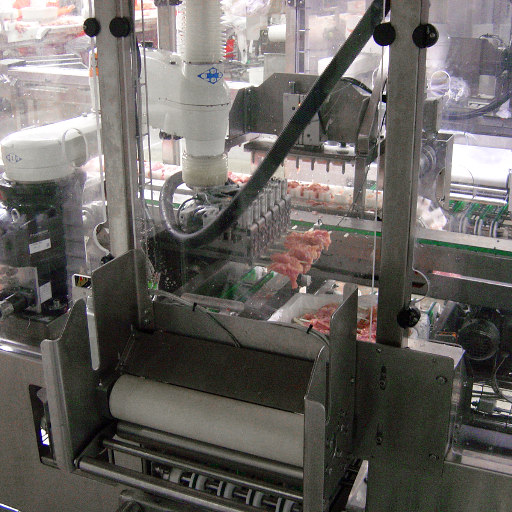

KFS170 Skewer production

System produces grill skewers. Skewer pieces arrive from the conveyor to the robot cell, where the robot puts pierces the skewer pieces with the stick and moves complete skewers into packages. In the end, packages are weighed and closed.

Capacity: 1500 skewers per hour.

VIDEO

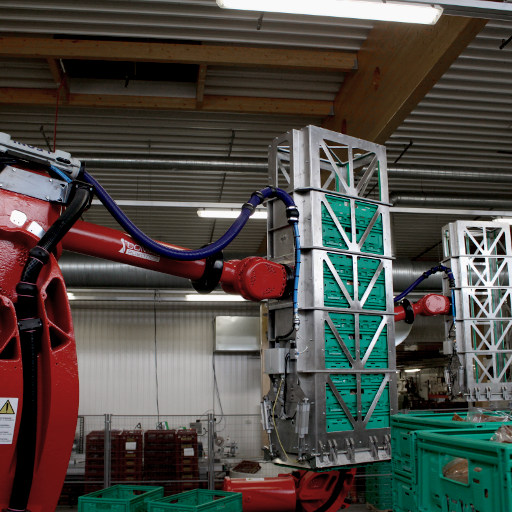

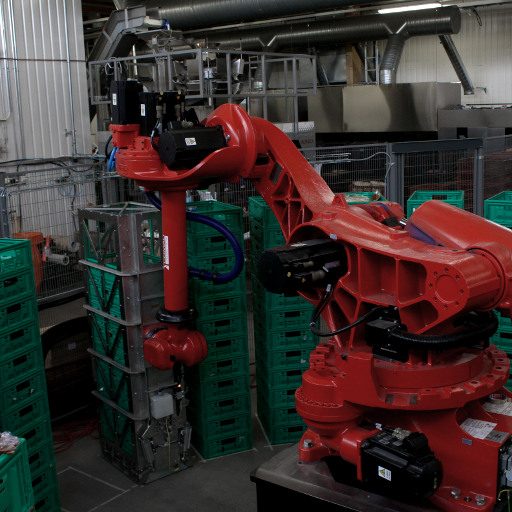

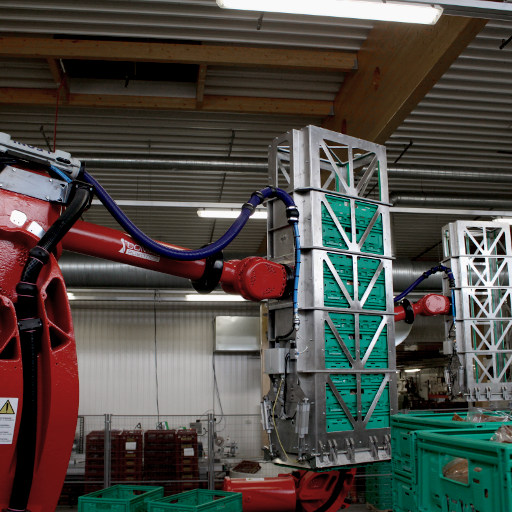

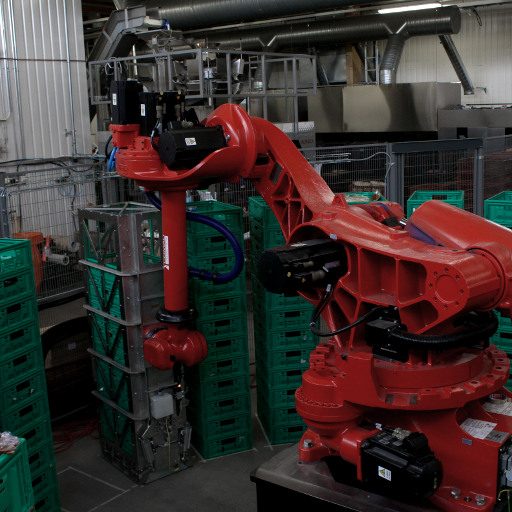

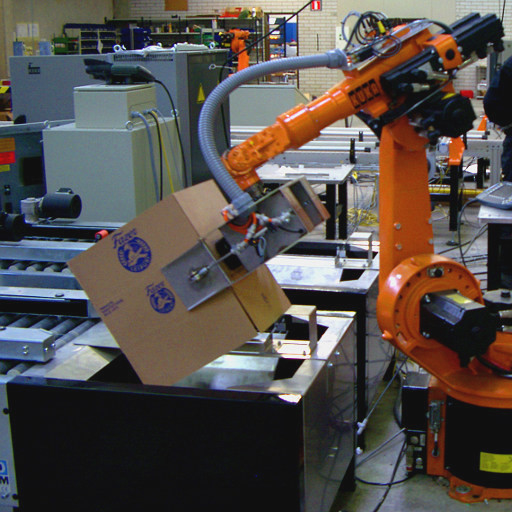

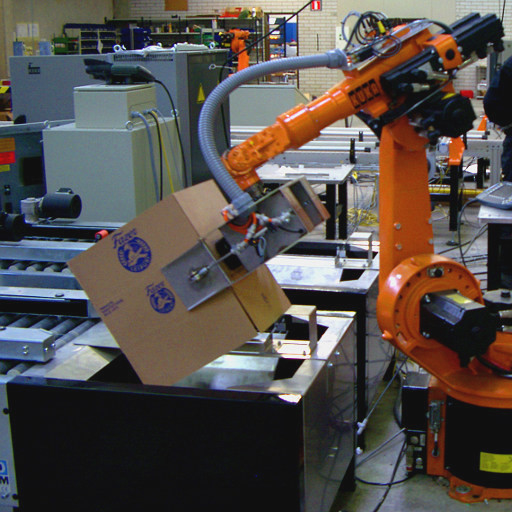

KFS163 Box palletizing

Palletizing robot, which functions with plastic and cardboard boxes. Direction recognition guarantees that the boxes are all facing the right direction. Special grippers can be chosen for different boxes, also for those cardboard boxes you cannot lift from above. If needed, the robot puts also a sheet between the layers.

Product: Carton or plastic boxes

Production capacity: 1400 boxes per hour

Use: The system is used by one person

Hardware:

- KUKA robot KR 100 PA, 4 palletizers

- KUKA robot KR 180 PA, palletizer for carton boxes

- KUKA robot KR 16, labeling robot

- special grippers for robots

- conveyors

- wrapping machine

- user interface

- pallet handling

- cardboard sheet handling

Software:

- robot programs

- data collection

- entire system logic program

Service and maintenance:

- scheduled twice a year

- due to modularity, other parts of the system can be used during the maintenance service

KFS154 Bottle draining

Robot drains bottles with passed best before dates or with spoiled contents. It takes a bottle crate from a pallet, opens bottle tops and empties bottles into the tank. The robot puts empty bottles back into crates and then onto pallets.

Properties:

- KUKA robot KR 100 comp

- grippers for 0,5 ja 1,5 l crates

- automatic gripper change

- pallet recognizer

Capacity: 1200 bottles per hour

VIDEO

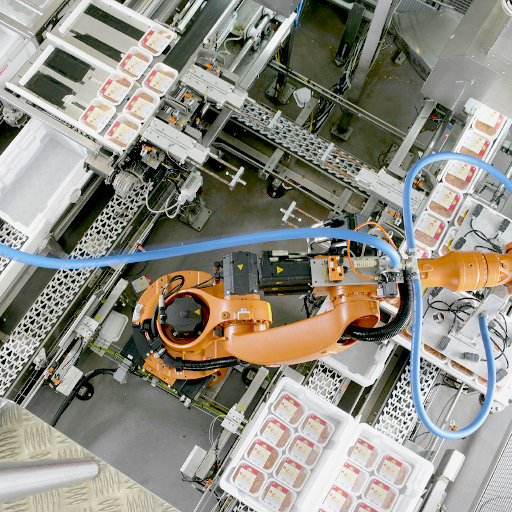

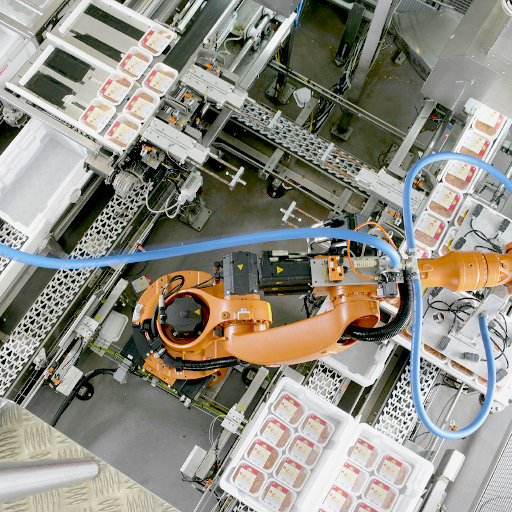

KFS136 Box packing for food packages

Food packages move in the conveyor from packing machine to the robot. Machine vision measures the packages, rejects defective packages, and robot moves packages into boxes.

Product: Food packages, three sizes

Production capacity: 100 packages per minute

Use: The system is used by one person

Hardware:

- KUKA robot KR16

- suction cup gripper

- machine vision

- conveyors

- controllers

- control panels

Software:

- KRL robot software

- robot program

- safety logic

- data collection

Service and maintenance:

- scheduled twice a year

- production stoppage one day

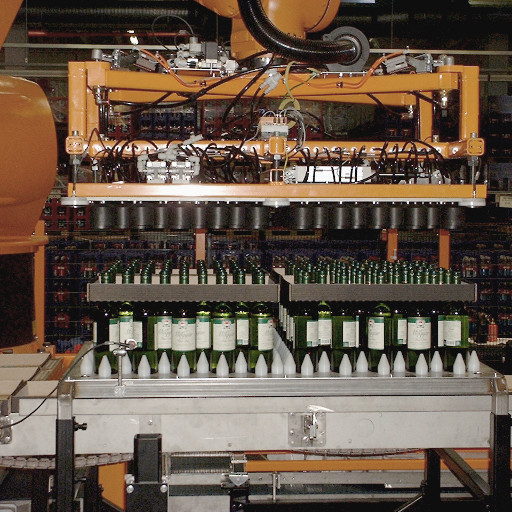

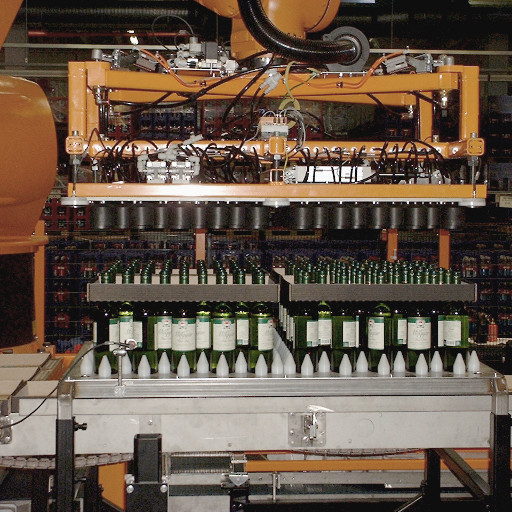

KFS131 Plastic tray packing for bottle

Robot takes bottles from the conveyor and puts them on a plastic tray, which is on a pallet or a dolly. The same robot moves also the plastic trays.

Properties:

- KUKA robot KR 40 PA

- gripper for bottles

- moving and transporting dolly or pallet

- handling of plastic trays

- software

- control panel

- quality check of the product

Nominal capacity (=differs from case to case): 1000 bottles per hour

KFS127 Carton box production

The robot takes the blank cardboard box from the pile, opens it, places it into the taping machine and tapes it. The robot piles ready boxes in a depot.

Properties:

- KUKA robot KR 16

- KINE gripper/opener

- cardboard box depot

- taping machine

- box folding programm

Capacity: 250 boxes per hour

KFS126 Box packing for bags

Bags are inputed from bakery's production line into the system. Robot packs bags into boxes using in a certain order. The boxes are stacked and then moved forward as stacks.

Capacity: 20000 breads per hour.

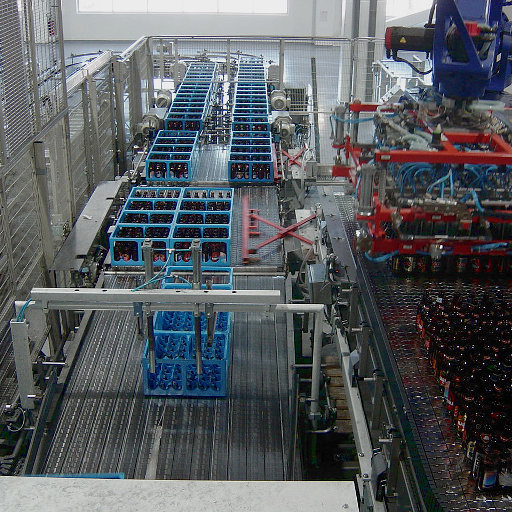

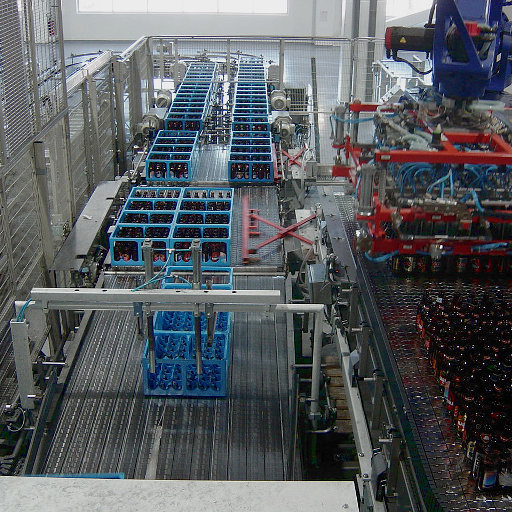

KFS121 Returnable bottle unloading

Returnable bottles are removed from crates or plastic trays, and are then lifted to the conveyor. Empty crates or plastic trays are then placed on a pallet.

Properties:

- KUKA robot KR 180 PA

- grippers for bottles, crates and plastic trays

- unpacking program

- control panel

Capacity: 7000 bottles per hour

KFS109 Bag in box products palletizing

This robot takes the products from the conveyor and palletizes them. The pallets are automatically brought to palletizing place and moved forward to wrapping machine. This robot is suitable for wine packs with faucets and other BIB products.

Properties:

- KUKA robot KR 40 PA

- BIB gripper

- moving and transport of dollies or pallets

- software

- control panel

- handling cardboard sheets

Nominal capacity: 700 boxes per hour

KFS103 Plastic tray washing

Dirty plastic trays are in pallets, from which robot picks them and places them in to a conveyor, where they are moved to washing. The trays are washed in a washing tunnel and then dried in a drying tunnel. Clean trays are palletized and moved forward into pallet loading area.

Capacity and acceptance criteria: 800 plastic trays per hour and maximum residual moisture content value 5 grams per plastic tray.